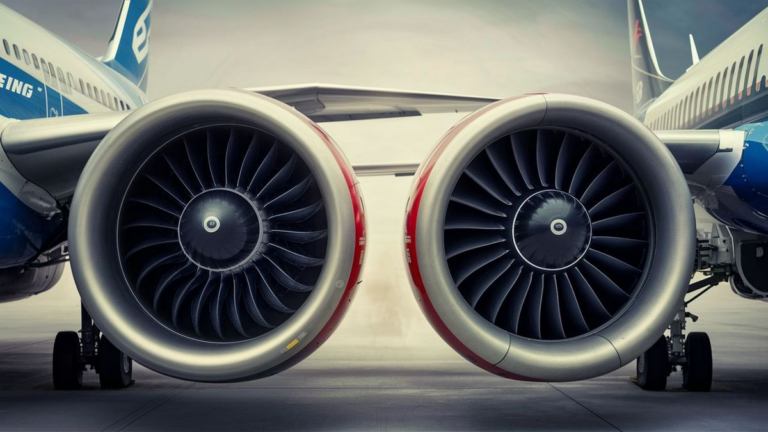

When it comes to comparing the engines of the Boeing 777 and the Boeing 737, two of the most iconic aircraft in the aviation industry, several key differences and similarities emerge. Both aircraft belong to Boeing’s extensive lineup, catering to different market segments and operational needs.

Overview of Boeing 777 Engine

The Boeing 777 is renowned for its powerful engines, which are essential for its long-haul capabilities and ability to carry a significant number of passengers over vast distances. The 777 typically utilizes engines from two major manufacturers: General Electric, Rolls-Royce, and Pratt & Whitney.

Overview of Boeing 737 Engine

In contrast, the Boeing 737, while also equipped with reliable engines, is designed for shorter routes and regional flights. The 737 family has been a workhorse in the commercial aviation sector for decades, with engines primarily sourced from CFM International, a joint venture between General Electric and Safran Aircraft Engines.

Performance Comparison

One of the primary distinctions between the engines of the Boeing 777 and the Boeing 737 lies in their performance characteristics. The engines fitted on the 777 are optimized for long-range efficiency and high thrust, enabling the aircraft to cruise at higher altitudes and speeds, making it suitable for intercontinental flights.

On the other hand, the engines powering the 737 are designed for shorter takeoff and landing distances, as well as fuel efficiency during shorter flights. This difference in performance reflects the diverse operational requirements of these aircraft.

Technological Advancements

Both the Boeing 777 and the 737 benefit from continuous technological advancements in engine design and efficiency. Over the years, manufacturers have introduced improvements aimed at enhancing fuel efficiency, reducing emissions, and increasing reliability.

These advancements often trickle down from flagship models to smaller aircraft, ensuring that both the 777 and the 737 remain at the forefront of aviation technology.

Environmental Considerations

In recent years, environmental concerns have prompted aircraft manufacturers and airlines to prioritize sustainability and emissions reduction. Both the Boeing 777 and the 737 have undergone updates and modifications to comply with stringent environmental regulations.

Efforts to minimize carbon footprint and noise pollution have led to the development of quieter and more fuel-efficient engines, benefiting not only the airlines but also the communities surrounding airports.

While the Boeing 777 and the 737 serve different segments of the aviation market, their engines play a crucial role in defining their capabilities and operational efficiency. Whether flying passengers across continents or shuttling between regional destinations, both aircraft rely on advanced engine technology to ensure safety, reliability, and performance.

In summary, while the Boeing 777 boasts powerful engines optimized for long-haul flights, the Boeing 737 excels in shorter routes with its efficient and reliable powerplants. Understanding the nuances of each aircraft’s engine capabilities is essential for airlines and aviation enthusiasts alike.

Engine Maintenance

Engine maintenance is a critical aspect of ensuring the longevity and performance of both Boeing 777 and 737 aircraft. While the engines of these planes are designed to withstand rigorous operations, routine maintenance schedules are essential to prevent unexpected failures and optimize efficiency.

Boeing, along with engine manufacturers such as General Electric, Rolls-Royce, Pratt & Whitney, and CFM International, provides comprehensive maintenance guidelines and support services to airlines worldwide. These guidelines encompass regular inspections, component replacements, and performance monitoring to uphold safety standards and regulatory requirements.

Factors Impacting Maintenance

Various factors influence engine maintenance schedules, including the number of flight cycles, operating conditions, and environmental factors. Airlines analyze data from flight operations to determine the optimal intervals for inspections and overhauls, minimizing downtime and maximizing fleet reliability.

Furthermore, advancements in predictive maintenance technologies, such as data analytics and sensor monitoring, enable airlines to anticipate potential issues before they escalate, reducing operational disruptions and maintenance costs.

Cost Considerations

Engine maintenance represents a significant portion of an airline’s operational expenses. Balancing maintenance costs with operational efficiency is paramount for airlines seeking to optimize their bottom line while ensuring safety and reliability.

Modern engine maintenance programs offer flexible options, including pay-per-hour agreements and comprehensive service packages, tailored to the specific needs of each airline. These programs provide predictable maintenance costs and access to expert technical support, enabling airlines to focus on their core business operations.

| Aspect | Boeing 777 | Boeing 737 |

|---|---|---|

| Typical Routes | Long-haul, intercontinental flights | Short-haul, regional flights |

| Engine Manufacturers | General Electric, Rolls-Royce, Pratt & Whitney | CFM International (General Electric & Safran Aircraft Engines) |

| Performance Focus | Efficiency at high altitudes and speeds | Short takeoff and landing, fuel efficiency |

Frequently Asked Questions

- Are Boeing 777 engines more fuel-efficient than those of the 737?

- Do airlines have preferences for specific engine manufacturers?

- How do advancements in engine technology benefit aircraft performance?

The engines of the Boeing 777 are optimized for long-range efficiency, making them more fuel-efficient for extended flights compared to the 737, which prioritizes efficiency during shorter routes.

Airlines often select engine options based on factors such as performance, reliability, and maintenance costs. Preferences may vary depending on the airline’s operational requirements and fleet strategy.

Advancements in engine technology contribute to improved fuel efficiency, reduced emissions, and enhanced reliability, ultimately enhancing aircraft performance and operational economics.

See also: